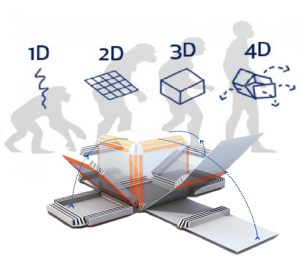

A new generation of additive manufacturing, 4D printers, copies the nature to create 3D objects that can change their shapes after they are printed. The basis of the method was borrowed from the flowers bending and twisting their petals depending on the light and humidity in the environment.

“Other active research teams exploring 4D printing require multiple materials printed together, with one material that stays rigid while another changes shape and acts like a hinge,” said Jennifer Lewi, a materials scientist, at Harvard University.

Jennifer Lewi with her colleagues aimed to find homogeneous material for 4D printing to make the process simpler. And they indeed have found it exploring how plants react to environmental factors such as light and touch.

The main constructing fiber of plants is cellulose. The same material, stiff cellulose plunged in a soft hydrogel, was used in 3D printers by researchers from Harvard University. As it is known, the hydrogel swells when it is put in water. This quality lets the scientists control the directions in which fibers tend to change within the printed structures. While orientations of fiber control the way in which these patterns grow when they are immersed in water. Moreover the scientists can even program shape changings of the material using the orientations of cellulose fibers.

One day 4D printed structures will be engaged in living cells for more effective wound recovery, will be used in robotic surgical tools and will be implemented into smart textiles that change their configuration according to humidity, temperature and other factors. Just imagine a pair of smart 4D printed shoes that can feel the warmth and humidity of your feet and tighten the laces like in the famous movie “Back to the Future”. That is the future I am looking for.

Source: https://www.livescience.com/53477-shape-shifting-4d-printed-objects.html